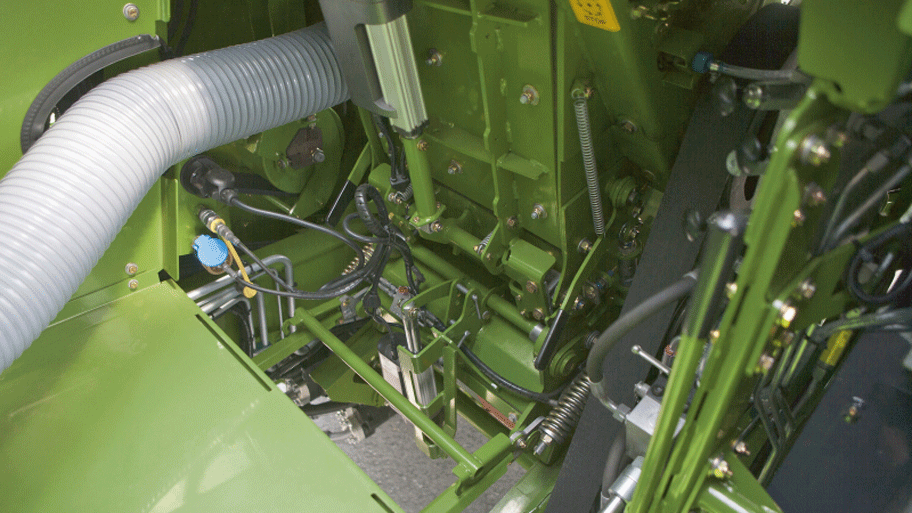

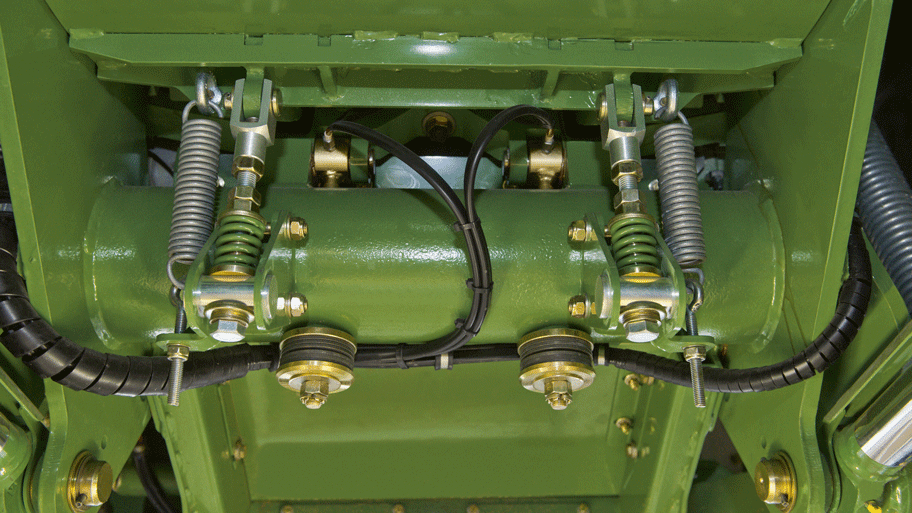

When KRONE’s first pre-series BiG X 480 forage harvester rolled off the factory product line it was, as usual, closely inspected by the company’s senior management team. The cable harness installation received favorable comments for being exceptionally clean and well executed, setting new standards for a company that makes top quality a hallmark of all its products.

KRONE, a major brand in the agricultural machinery market, implemented an interdisciplinary product development process.

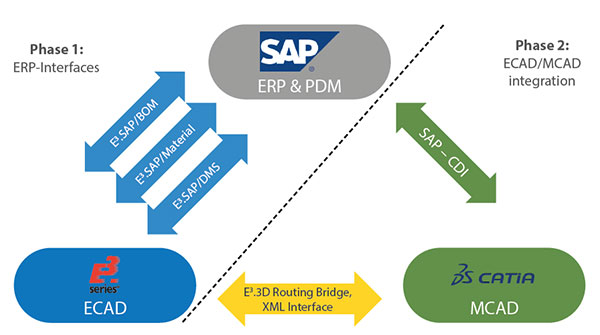

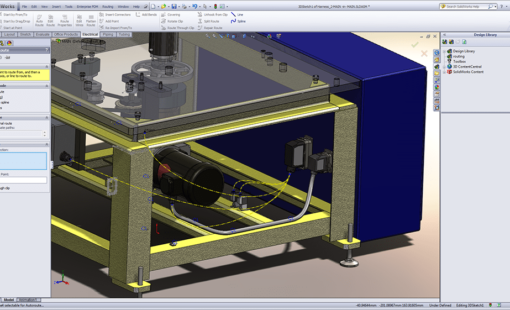

Using Zuken’s E3.series, KRONE linked ECAD, MCAD and ERP to develop an integrated digital engineering and sourcing process, achieving sizable benefits for both sourcing and service. With an integral representation of mechanical and electrical product information, KRONE was able to make solid progress in implementing its major business optimization strategies: Industry 4.0 and Farming 4.0.

Results

KRONE had been using Zuken’s E3.series electrical design tools since 2006, but mainly for documentation purposes. “The integration and process support capabilities provided by E3.series were largely unused during the initial years, ,” recalls Dr. Korn, CIO of the KRONE Group. It was my colleagues from electrical engineering and technical IT departments who promoted E3.series and its integration into our sourcing and mechanical engineering processes. Up to that time, the cable harness was more or less an afterthought, which was designed after the mechanical design was close to completion.”

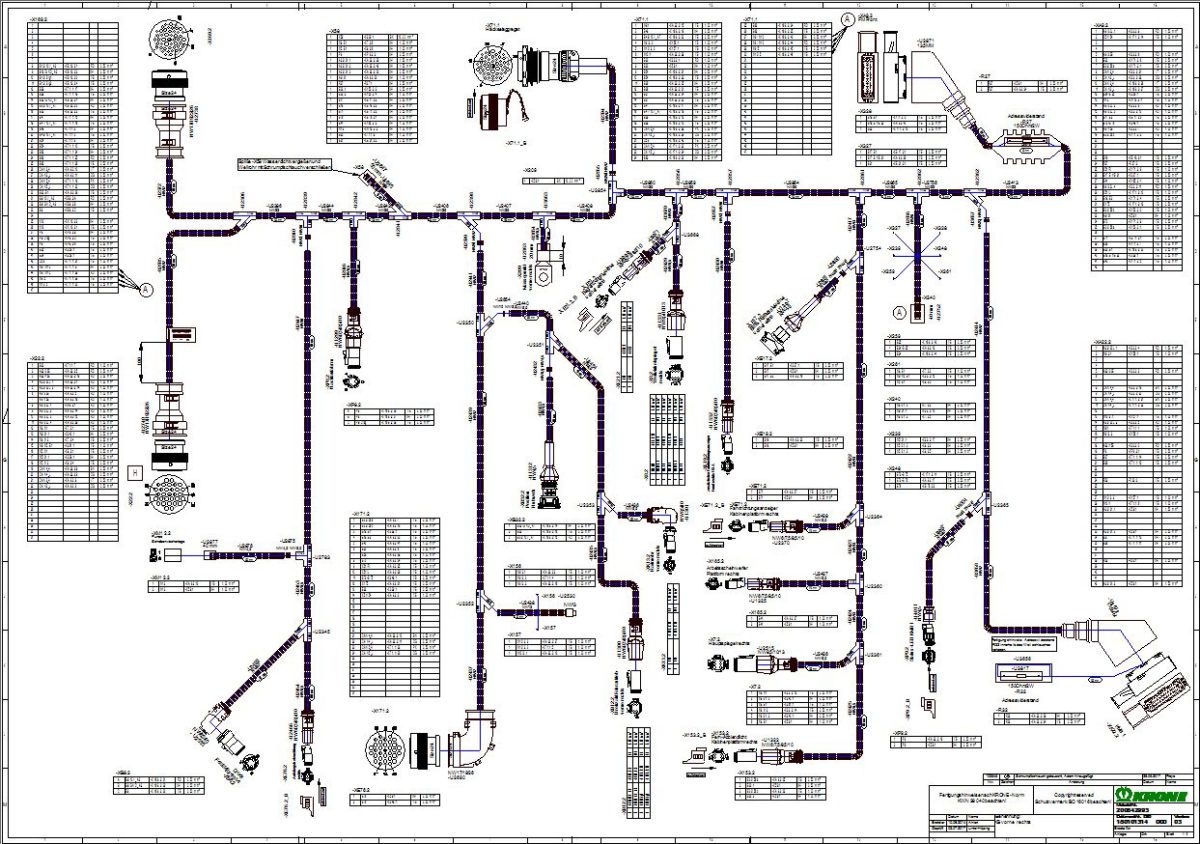

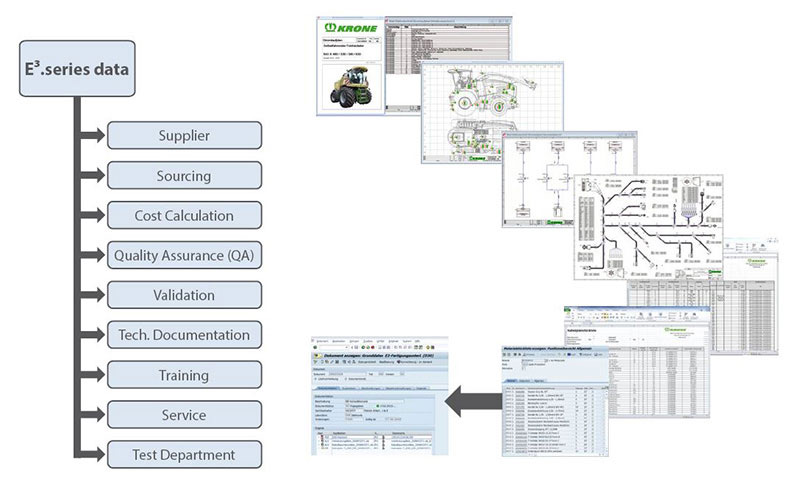

A unified company specific design methodology was developed which involved the creation of companyspecific templates for E3.series schematic and cabling designs. In addition, material master data records were cleaned up in KRONE’s SAP-system and a new classification scheme for the electrical components was introduced. This provided the basis for the definition of automated E3.series reports to generate digital bills-of-material and connection tables that could be transferred directly to be reused in sourcing and production.

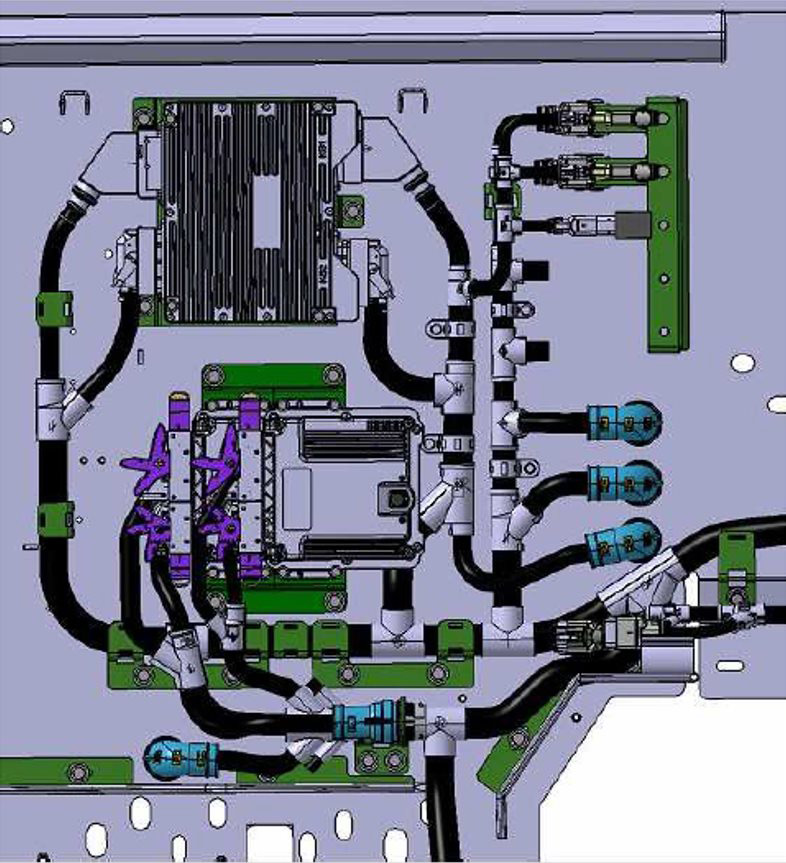

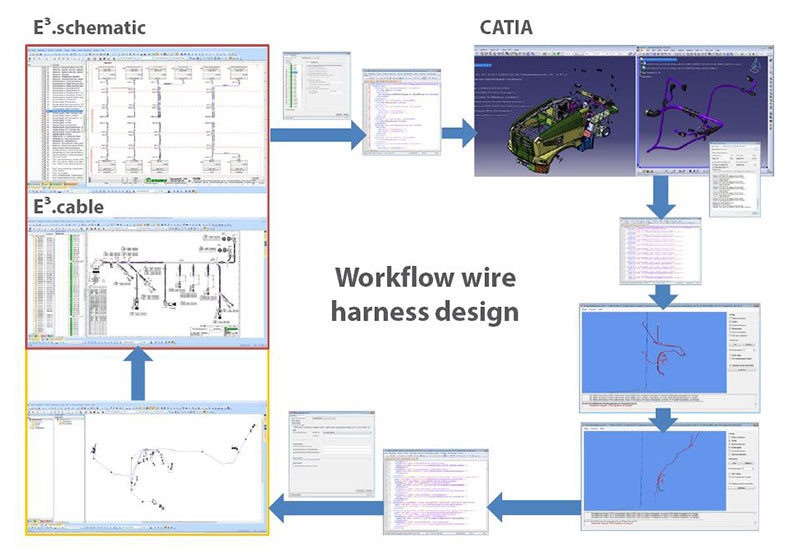

As both CATIA V5 and E3.series were established technologies in mechanical and electrical engineering respectively, it was a logical step to think about ways of combining them so that key parameters could be exchanged and modifications carried out on both ends in a coordinated manner. The solution was built using the E3.series product option E3.3D Routing Bridge that enables a bidirectional exchange of schematic and connection information between E3.series to CATIA, Creo and other leading 3rd party MCAD systems. .

Although the solution was initially designed and driven by KRONE’s electrical engineering department, it now provides tangible benefits for a number of downstream operations: “We are now finding ourselves in the middle of a discussion about Industry 4.0 and digitization, and we are finding that our integrated data model combining digital mechanical and electrical data is bringing us close to what is today referred to as the digital twin.Today, we have all mechanical, hydraulic and electrical assemblies available in one information source, and that puts us in a position to build a number of robust downstream processes on them,” concludes Dr. Korn.

Related products

Discover more about the products that helped Krone

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.