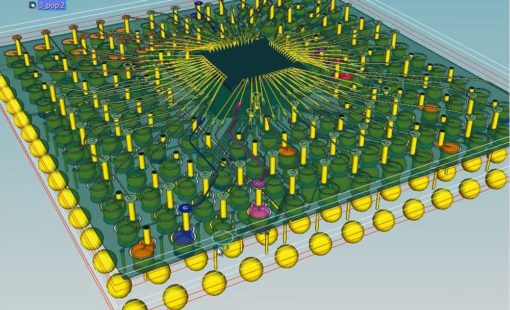

Reduction of board and module size was achieved by combining chip, package, and board into a 3D design structure for co-design feasibility studies.

Zuken’s CR-8000 Design Force enabled engineers to easily and quickly switch design context as they proceeded through the design process. When they needed to design the package in 3D, a click of a button switched to 3D mode, with another click, they were back in 2D, and with another click of a button they could design in the IC.

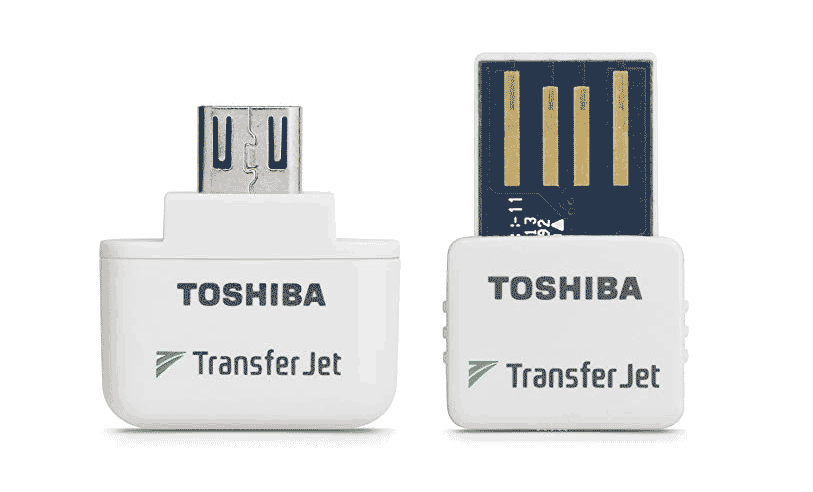

RF Module Shrink (TransferJetTM)

RF Module Shrink (TransferJetTM)