Share and analyze detailed harness data created by different authoring tools

E3.harnessAnalyzer is a powerful tool for viewing and analyzing harness drawings in the HCV container data format. HCV is an extension of industry standard KBL (physical data model) and SVG (vector graphics) data. A key benefit is the ability to manage configurations based on modules for customer-specific harnesses (KSK). These features provide a new level of ease-of-use when sharing the comprehensive harness design model and documents with internal or external project teams.

Share and analyze detailed harness data created by different authoring tools

Read KBL, VEC, HCV, and other design data formats

Visualize harnesses and variants in 2D and 3D

Manage configurations based on modules for customer-specific harnesses (KSK)

E3.HarnessAnalyzer paves the way for harness design collaboration in the demanding automotive, special vehicles and wider transportation industries. It is easy to use and allows efficient viewing, browsing, analyzing, validating and commenting on the design model and related drawings generated by today’s growing number of authoring tools. The tool enables OEMs to optimize their process chain and collaborate with their suppliers. It allows detailed harness data to be made available to all stakeholders, such as release engineers, quality inspectors and production planners.

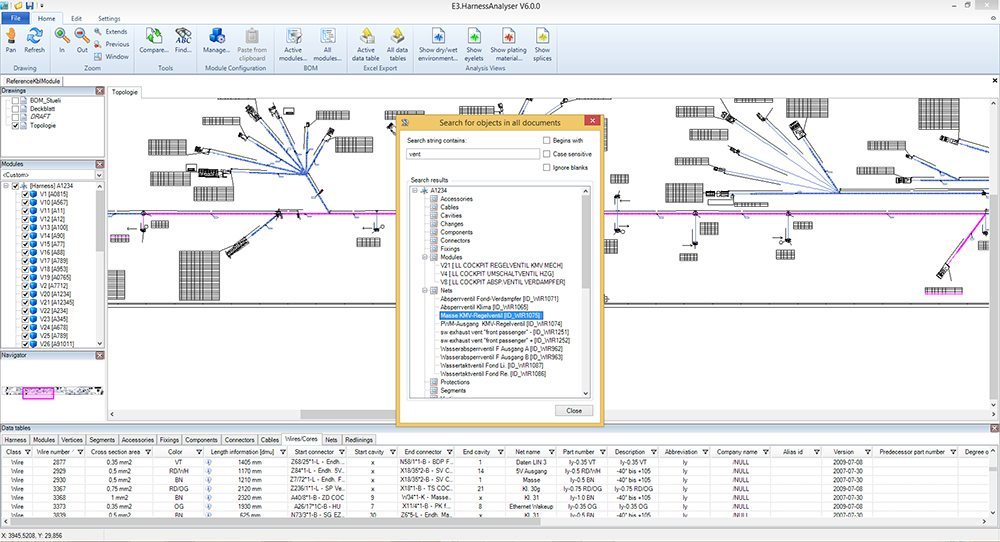

Viewing and analyzing harness drawings

Leveraging the 3D-coordinates in the imported data (KBL, VEC or PLMXML), E3.Harness Analyzer can render haresses as a full 3D model. When a 2D drawing is included in the import data (HVC or DSI), the tool can also visualize the detailed 2D-drawing in high resolution and XXL-scale formats (e.g. 1m x 60m)

With today’s large designs and drawings, the search function has become a major day-to-day requirement. E3.Harness Analyzer supports this with a powerful search engine functionality across all technical objects of a design

Design collaboration typically involves fast manual detection of changes made by other designers when a new harness drawing version is released. E3.Harness Analyzer quickly and automatically compares two versions of same document and cross-highlights the drawing to show differences. Results may be exported to Microsoft Excel.

With E3.Harness Analyzer users can mark-up documents with textual comments structured by classes such as “error” or “confirmation”, which are displayed as flags in the drawing. All annotations can be exported for downstream processing, such as design review in the original authoring system or archiving for change management.

Master harness drawings may contain module families along with their modules. E3.Harness Analyzer displays the related information on module families and modules according to STEP AP212 KBL data structure, including the module history. The module structure can be used to filter the information in views and lists for a single module or any combination of modules.

See how E3.HarnessAnalyzer allows viewing, browsing, analyzing, validating and commenting on the design model and related drawings

E3.HarnessAnalyzer supports the display of wire harnesses as both 2D and 3D structures. The 3D capability is based on 3D coordinates that are specified in KBL, VEC or PLMXML structures. Leveraging these coordinates, E3.HarnessAnalyzer generates a dynamic 3D representation that is directly coupled to the KBL data model.

In addition to topological information, KBL, VEC and PLMXML data also contain connectivity information of wire harnesses and their components. Leveraging this information, E3.HarnessAnalyzer can generate schematic views applying user-defined filter criteria. The schematic is then automatically compiled in a fraction of a second. The generated diagram is fully linked to the 2D and 3D view

Master harness drawings may contain module families along with their modules. E3.HarnessAnalyzer displays the related information on module families and modules according to STEP AP212 KBL data structure – module history information included. The module structure can be used to filter the information in views and lists for the content of a single module or an arbitrary combination of modules.

Supported import formats include native PLMXML and DSI capabilities. In addition, E3.HarnessAnalyzer now supports the import of data in the latest VEC (Vehicle Electric Container) industry standard format, thereby enabling review and inspection capabilities for comprehensive 150% wire harness designs, including their full range of options and variants.

Start Your Test Drive Today