Wire Harness Manufacturing Documentation

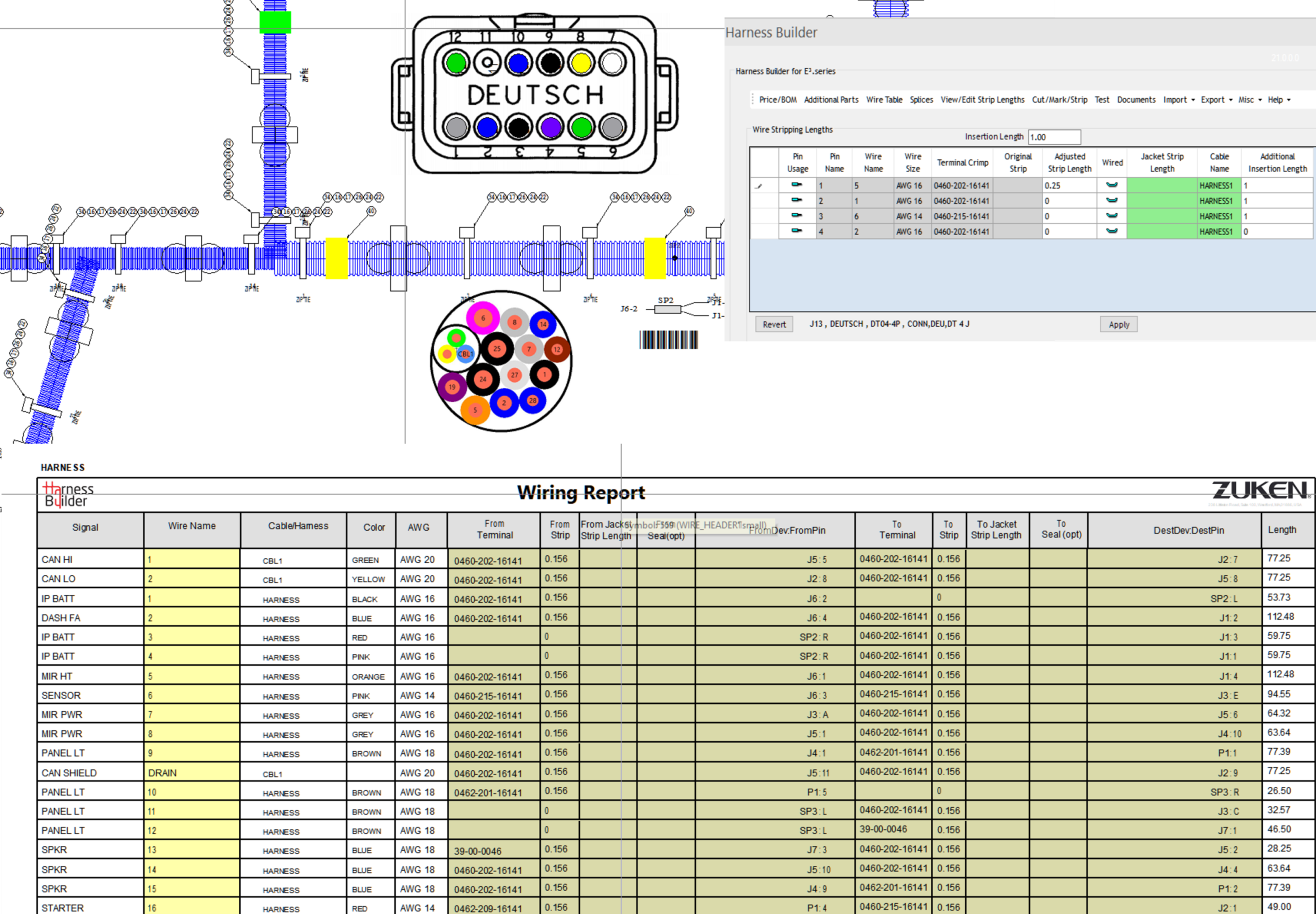

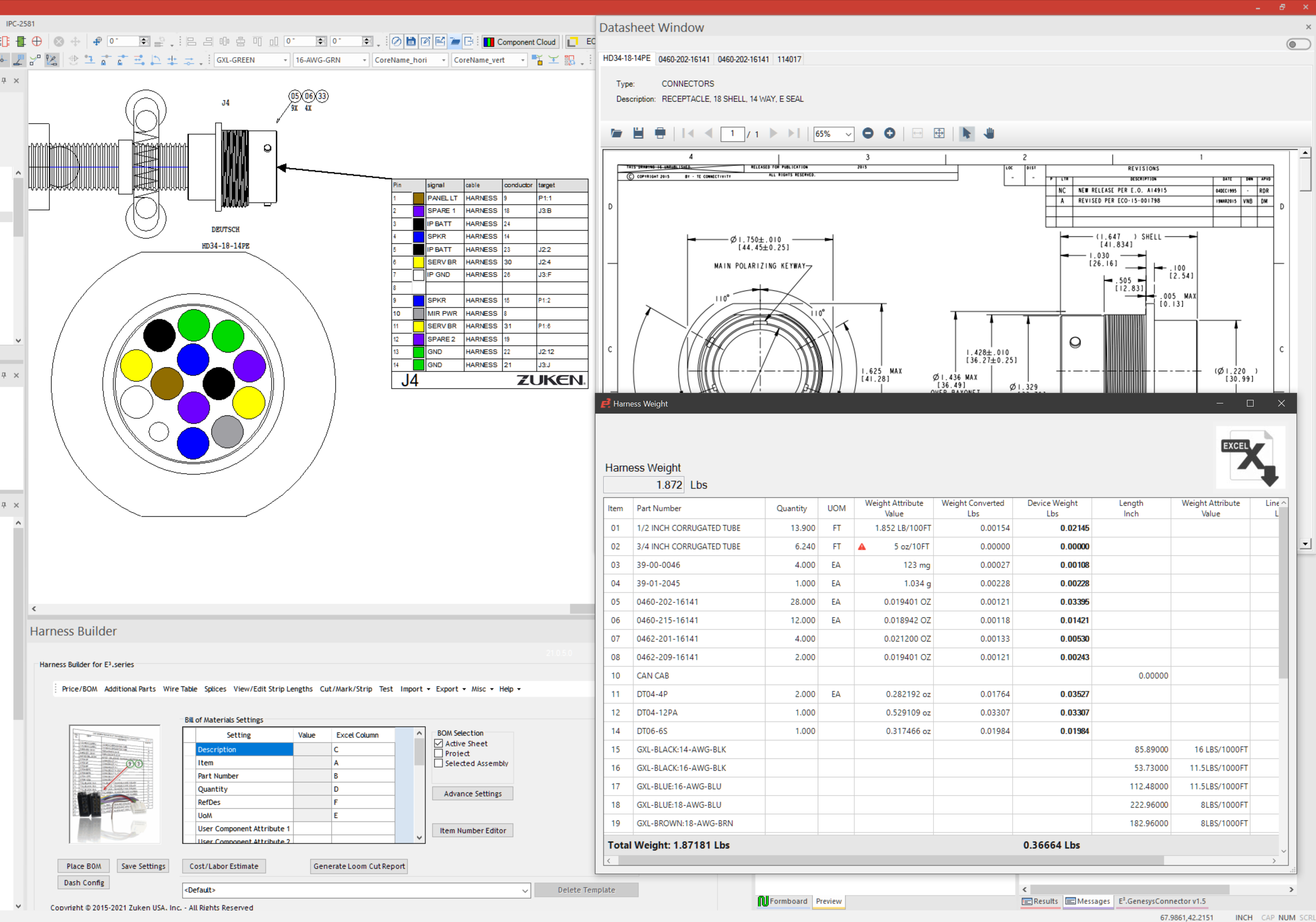

E3.formboard is a complete solution for creating wiring harness drawings for manufacturing. On any sheet size, one or more manufacturing drawings can be created. Automatic functionality makes placing, arranging, and dimensioning the harness and its segments easier. There is a complete integration of E3.cable and E3.formboard. With E3.series top-down or bottom-up design approach, projects can either start with the logical interconnection data or the harness layout. The logical interconnection data defined in E3.cable is used directly in E3.formboard, and any changes reflect automatically in the other when made in either module.